Many dental laboratories rely on the exocad Implant Module for designing individual abutments, screw-retained crowns and bridges, making it one of the most widely used modules within DentalCAD. In the Chemnitz release, two key workflow steps have been optimised to help dental technicians achieve the desired abutment shape more quickly and efficiently. The core workflow remains unchanged, ensuring that users can transition seamlessly. What’s new? The steps “Detect implant position” and “Abutment design” have been updated.

Implant and prosthetic components workflow: What’s new

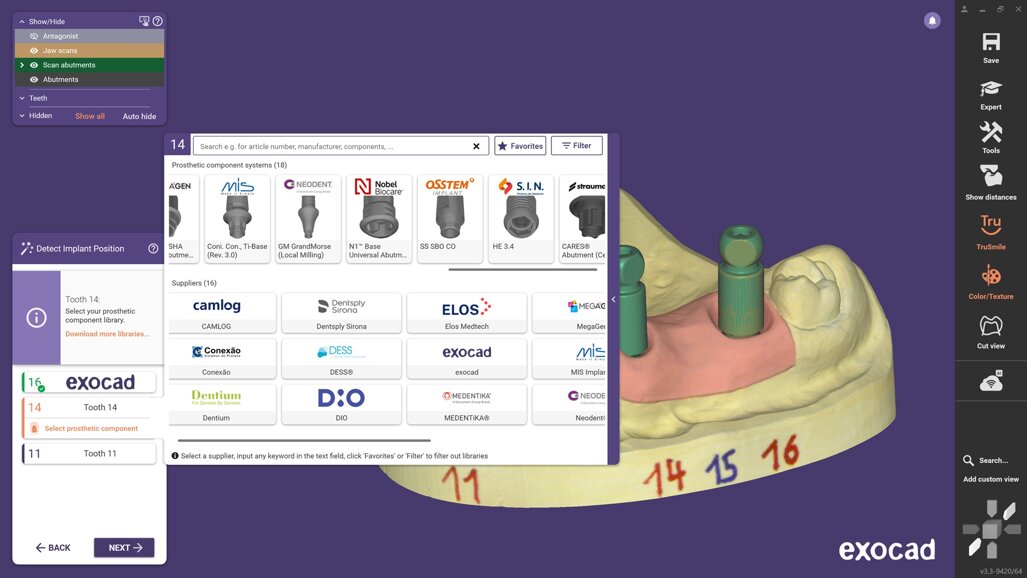

With DentalCAD 3.3 Chemnitz, selecting implant and prosthetic components has become simpler, faster and more flexible. When designing individual abutments for multiple implants in one jaw, users can now select and position all implants in a single step (Fig. 1). This results in significant time savings compared with the previous workflow, in which each implant had to be handled individually.

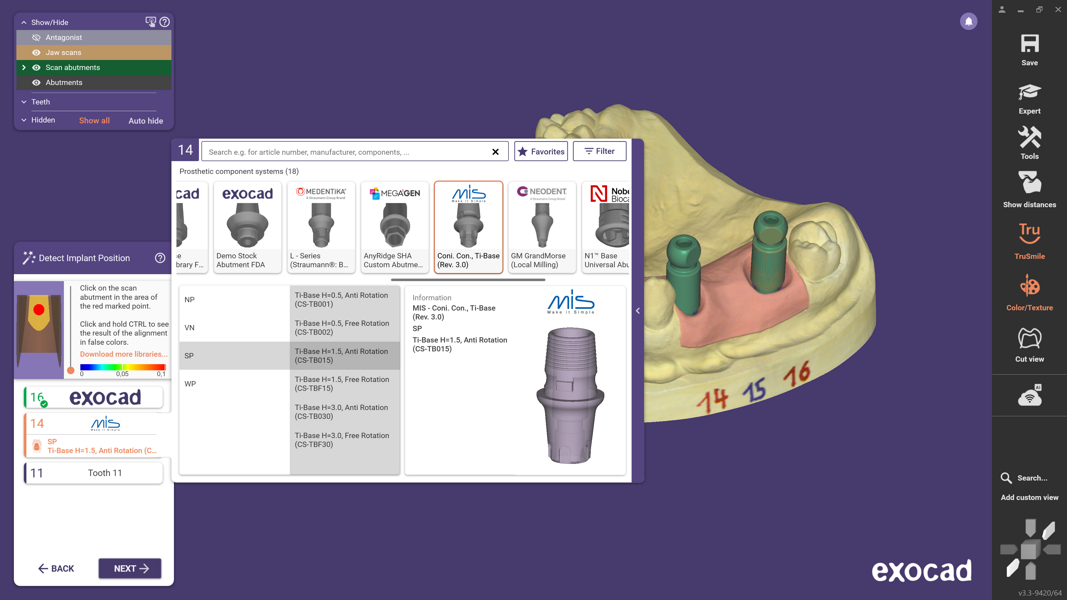

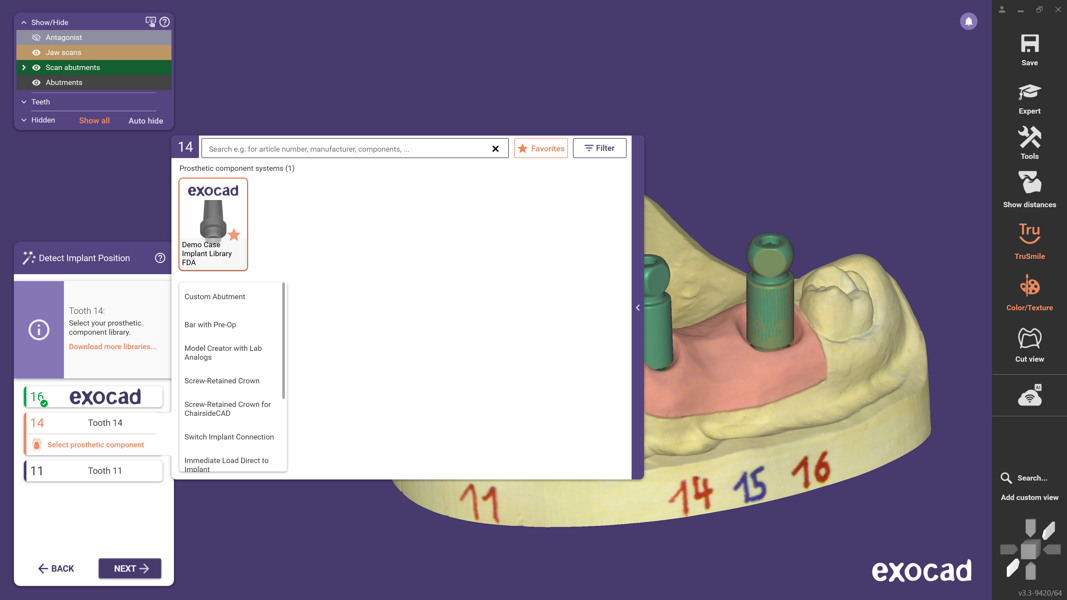

To help users find the appropriate components for an implant system more quickly and efficiently, exocad has enhanced the selection function to include search and filter options. When they click on their chosen implant in the implant component selection, they automatically see the components available for that implant system (Fig. 2). To speed up the search for the right components, users now have three options: new search function, advanced filter functions and setting favourites.

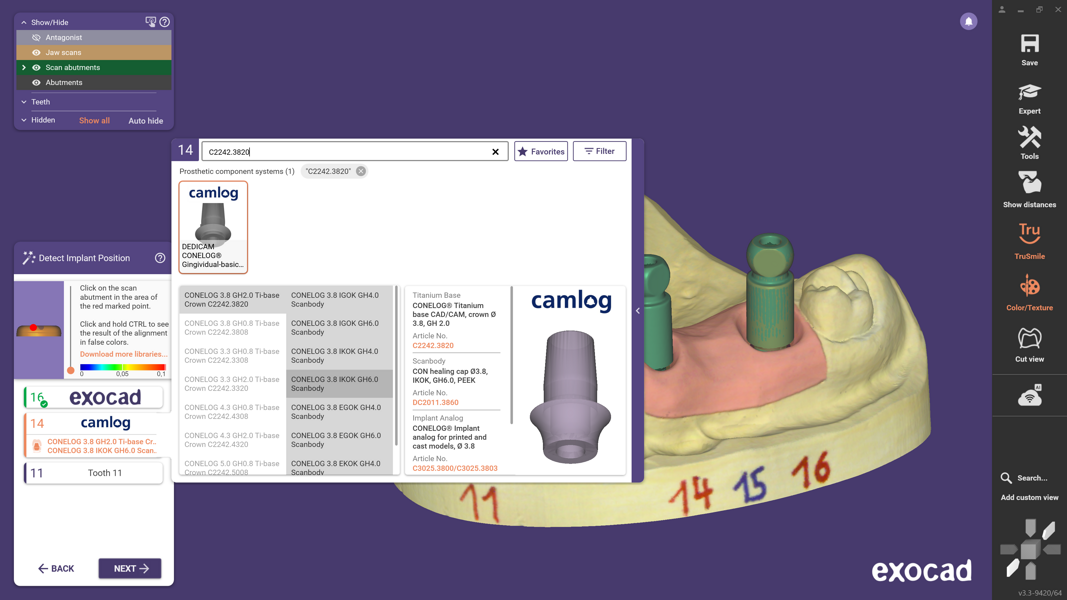

- Search: The new search field allows users to quickly locate the component they need for their individual abutment design. Search options include, for example, implant and component manufacturer, product name or component article number (Fig. 3).

- Filters: Users can also narrow the component search using filters. For example, they can filter by indication (Fig. 4), such as an angulated screw channel.

- Favourites: Frequently used components can be marked with stars. Favourites are then displayed first (Fig. 5).

Abutment design: What’s new

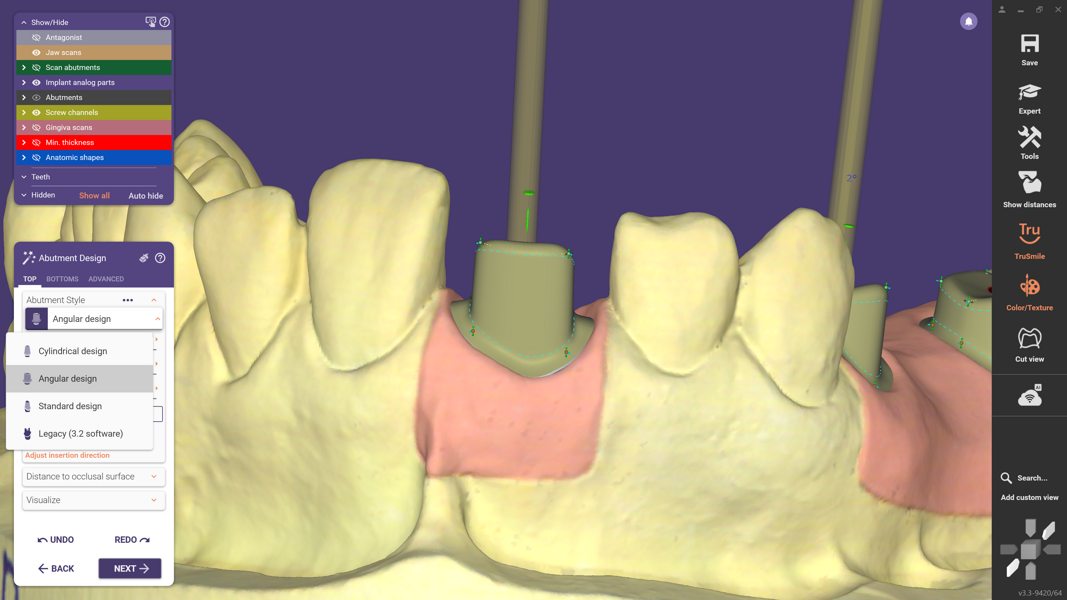

The workflow for designing the supragingival area of individual abutments has been significantly improved. Users can still revert to the previous design version at the start of the workflow when selecting an abutment style (Fig. 6), allowing laboratories to continue using familiar tools during busy production days.

Selecting an abutment style: Users can choose from cylindrical, angular and standard templates. The software now automatically suggests an initial design based on tooth position—molar, premolar or anterior (Fig. 7). These suggestions can be further customised and saved as personal abutment styles.

Creating custom abutment styles: Customised abutment styles for specific clinical situations can be saved under individual names. This allows each user to build a personal library of designs. For me, this option is a highlight of the Chemnitz release and my top tip for all Implant Module users.

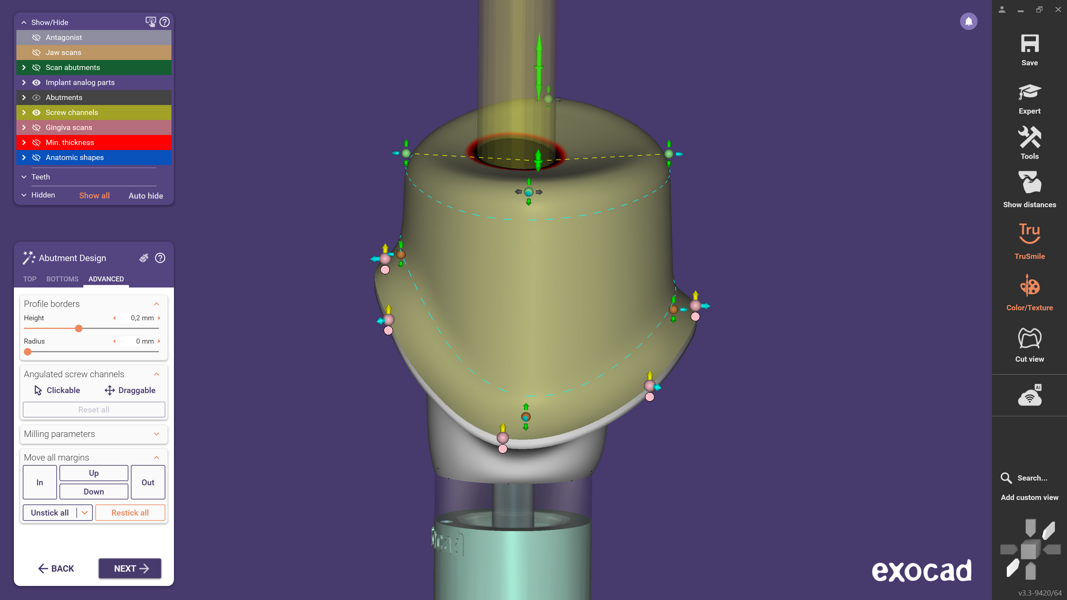

Control points: If a control point is moved beyond a functional limit—for example, outside the emergence profile or towards the centre—the software immediately provides a clear visual indication explaining the restriction.

New fissure line: The new fissure line reflects the fissure of the crown (Fig. 8). The thin yellow line is particularly useful for molar abutments and can be freely adjusted to follow the tooth morphology. Displaying the tooth shape provides additional orientation and enables faster, more precise designs.

Moving control points: When all control points are selected simultaneously, the entire abutment shape can now be rotated. This is useful for special indications, such as rotated tooth positions, when an automatically generated design requires minor adjustment.

Tip for experts: The Advanced tab reveals all supra- and subgingival control points, allowing multiple areas to be adjusted simultaneously (Fig. 9). I consider this a highlight for Implant Module experts.

Conclusion

The enhanced Implant Module in DentalCAD 3.3 Chemnitz supports faster, more efficient and more precise abutment design. Many users will quickly integrate the new features into their daily workflows, while those who prefer a gradual transition can continue using the previous design version.

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

International / International

International / International

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

To post a reply please login or register