Sinterex is a manufacturing company which specialises in the mass production of customised products using 3D printing technology (Additive Manufacturing). Dental Tribune MEA had the opportunity to meet with Julian Callanan, founder of Sinterex and ask more about the company.

DTMEA/CAPPmea: What is the story behind the idea of Sinterex?

Julian Callanan: Sinterex was created out of a passion for metal 3D printing technology. Metal 3D printing has been the fastest growing subset of the 3D printing phenomenon for several years now. Nearly all new Airbus and Boeing planes contain metal 3D printed parts. Elon Musk’s SpaceX rocket even has a metal 3D printed engine combustion chamber. We were excited by the tremendous potential of this technology and wanted to build a company to channel this innovation in the Middle East.

Your motto is: “Applying the 3D printing technologies of tomorrow to the supply chain problems of today”. Could you please tell us more about what Sinterex does?

At its heart, Sinterex is a manufacturing business. However, unlike traditional manufacturing businesses, our production equipment is metal 3D printers. When 3D printing is deployed for industrial production purposes, this is called ‘Additive Manufacturing’. Additive Manufacturing contrasts with traditional manufacturing methodologies because, instead of milling or subtracting material away, we are adding material to create functional end-use parts.

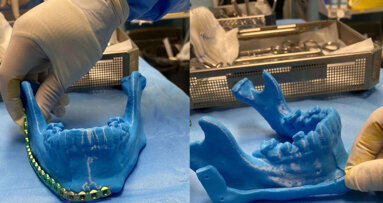

Currently, we use our metal 3D printers to produce highly accurate, patient-specific frameworks for Porcelain Fused Metal crowns and bridges. We can also metal 3D print surgical guides and removable partial dentures.

What is your manufacturing process?

Metal 3D printing works through a process called Powder Bed Fusion. Powder Bed Fusion sees a fine layer of metal powder, in our case a CE-certified bio-compatible Chrome Cobalt, rolled onto a plate. A 200w high-precision fibre laser is then used to selectively melt the metal powder to create the first layer of the desired shape. The accuracy of this laser is +/- 20 microns. To put this in context, a human red blood cell is about 5 microns, whilst a human hair is on average 75 microns wide.

After the laser has selectively melted the first layer, the plate drops, a new layer of powder is rolled, and the laser fires again. This process is repeated layer by layer, step by step, until the desired part is finished.

Why did you decide to do what you do in the UAE?

A number of factors meant that the UAE was a great home for Sinterex. Firstly, there are some fantastic clinics and dental laboratories here which are pushing further towards digital dentistry and embracing new production techniques. We felt that we could build good partnerships. Secondly, Dubai recently set out a strategic vision to create a 3D printing hub. We see the potential to collaborate with government agencies to achieve this vision. Thirdly, the UAE provides a great logistics hub for the broader GCC region. The British in the 1800’s used to refer to Dubai as Al Wasl, as it was, even then, a connecting point and meeting place for traders and business.

What is your target market at the moment and what are your expansion plans?

Our target market at the moment is dental laboratories in the Middle East region. We see ourselves as a supplier to these dental labs and our objective is to enable them to offer digital metal CAD / CAM solutions and to move away from time-consuming and potentially error-prone manual metal work.

For future expansion, we are listening carefully to our customers in the dental industry and having some great conversations about areas of further collaboration. At some stage in the future, we are also interested in stepping out into medical customised implant manufacturing. For now though, we remain focused on delivering great products and service to our existing customers and looking to add new customers.

How can the region benefit from this technology?

Both clinics and laboratories in the region can benefit significantly from this technology. For digitally-enabled companies, those with 3D scanners and 3D design software, we offer localised production at very short lead-times and much smaller prices than milling centres in Europe. For those companies which have not yet digitalised, we can help them to gain the benefits of digital production - accuracy, speed, reliability - without having to carry the costs of purchasing production equipment.

Just recently, you have printed the first 3D teeth here in Dubai, UAE; what was the process used?

This project was undertaken in collaboration with Middle East Dental Laboratory, a leading dental specialist and long-term proponent of digital and 3D printing in dentistry. Sinterex had responsibility for metal 3D printing a 12-unit tooth-borne bridge using the Powder Bed Fusion process outlined earlier. The team at the Middle East Dental Laboratory developed the design in collaboration with the Doctor and then finished the part and applied the ceramic veneering.

How does your technology benefit patients?

Patients benefit from gaining access to a technology which provides quicker and more accurate results than traditional manual techniques. For those patients who are interested in technology, they also benefit from being able to tell their friends that they have a 3D-printed smile!

What is the future of 3D printing in dentistry?

3D printing and dentistry are a perfect fit for one another. 3D printing enables the mass production of customised parts with high degrees of accuracy. Dentistry requires small and accurate patient-specific solutions. Therefore, the two are very well aligned. As time goes on, we may see the 3D printing of models becoming obsolete as intra-oral scanning and digital design improve. However, 3D printing for patient applications is here to stay.

It was about 12 years ago that I first came into contact with additive manufacturing technology, also known as 3D printing. Back then it was still a ...

LEIPZIG, Germany: The performance of the companies that supply dentists can be described as a thermometer in the mouth of dentistry at large. And whereas ...

JEDDAH, Saudi Arabia: Work-related musculoskeletal disorders are a significant and increasing problem. It is generally estimated that 60–90 per cent ...

The 13th CAD/CAM & Digital Dentistry Conference & Exhibition to be held by CAPP (Centre for Advanced Professional Practices) in May 2018 in Dubai, CAD/CAM, ...

RIYADH, Saudi Arabia: A Saudi Oral and Maxillofacial Surgery team working at King Fahd Specialist Hospital KFSH in Tabuk (northwestern Saudi Arabia) ...

Formlabs, a leading 3D printing company, today announces its partnership with Medit, a global provider of dental 3D scanners, to make chairside 3D printing ...

We’re here at the 13th CAD/CAM Conference in Dubai. This is the second time I’m here, the first time I was here was about three years ago at the tenth ...

Dental Tribune MEA had the pleasure to speak with Ahmed Ghandour who is Sales Director of Neoss. He has a strong track record in the dental implant ...

Mectron S.P.A, based in Italy, has revolutionised the dental surgery world with the development of piezoelectric bone surgery equipment. At the IDS show in ...

Live webinar

Tue. 24 February 2026

10:00 pm UAE (Dubai)

Prof. Dr. Markus B. Hürzeler

Live webinar

Wed. 25 February 2026

12:00 am UAE (Dubai)

Prof. Dr. Marcel A. Wainwright DDS, PhD

Live webinar

Wed. 25 February 2026

8:00 pm UAE (Dubai)

Prof. Dr. Daniel Edelhoff

Live webinar

Wed. 25 February 2026

10:00 pm UAE (Dubai)

Live webinar

Thu. 26 February 2026

5:00 am UAE (Dubai)

Live webinar

Tue. 3 March 2026

8:00 pm UAE (Dubai)

Dr. Omar Lugo Cirujano Maxilofacial

Live webinar

Wed. 4 March 2026

5:00 am UAE (Dubai)

Dr. Vasiliki Maseli DDS, MS, EdM

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

International / International

International / International

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

To post a reply please login or register